Gating System Design Calculation Pdf

Gating system design calculation pdf. Choke area mm W. Such a gating system is applied to increase the yield. Compared with the initial design it is found that the optimized casting design can decrease porosity around 18 while the yield increases 16.

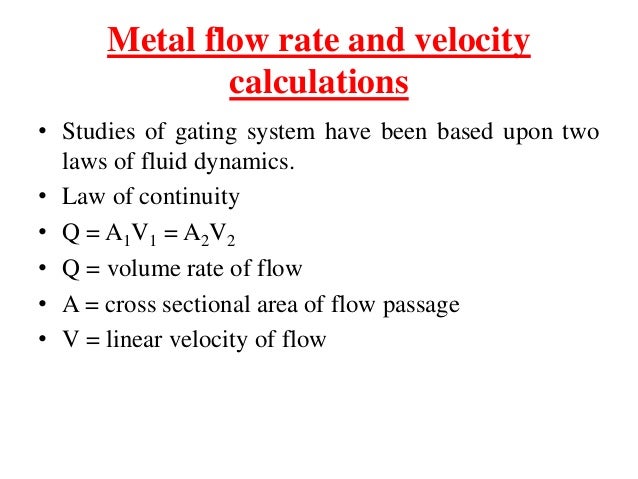

Avoid sudden or right angle changes in flow direction. Total gate CSA A Gating system is un-pressurized if area is increasing eg. Of feed metal would be supplied.

Feeding distance should be assumed to be a max-imum of 10 x M N. In this paper an attempt has been made to explain the major. Pattern thickness 6 000616 6096mm Pattern length 120 01216 12192mm.

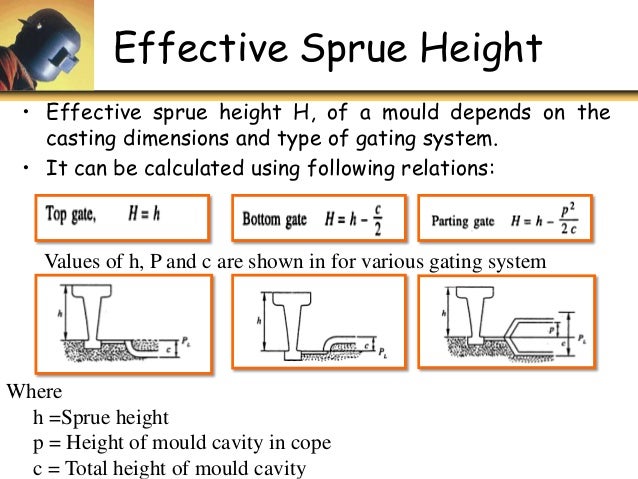

Gatingriser system design is critical to improving casting quality1. Input material properties and conditions. We selected Parting line gating system because to take advantages of top gating system and bottom gating system.

144 or pressurized if there is a constriction 483. Efficiency of the used gating system. GATING SYSTEM PPT 1.

If we have a casting with a significant modulus of 25 cm and a weight of 20 kg you get the following riser. Gating Ratio 2041097 Sprue Well Calculation. A gating system should fill the mold cavity completely before freezing.

Proper gating system will help to avoid turbulence flow of. Syms lamda1 lamda2 lamda3.

CLACULATIONS INVOLVING DESIGN OF FEEDING SYSTEM 1.

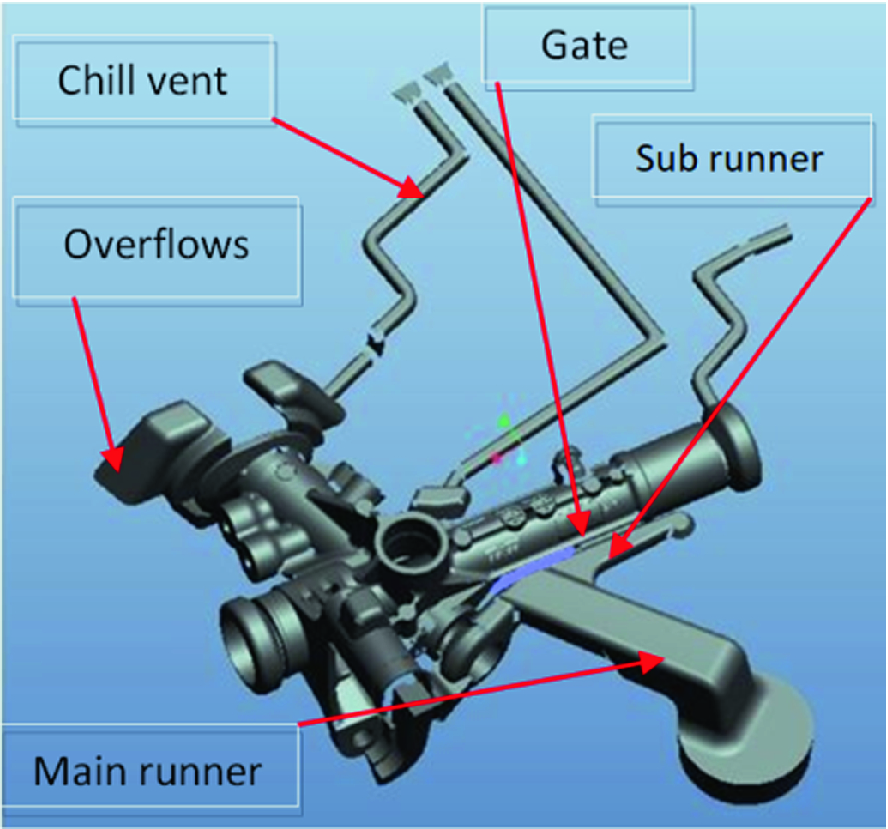

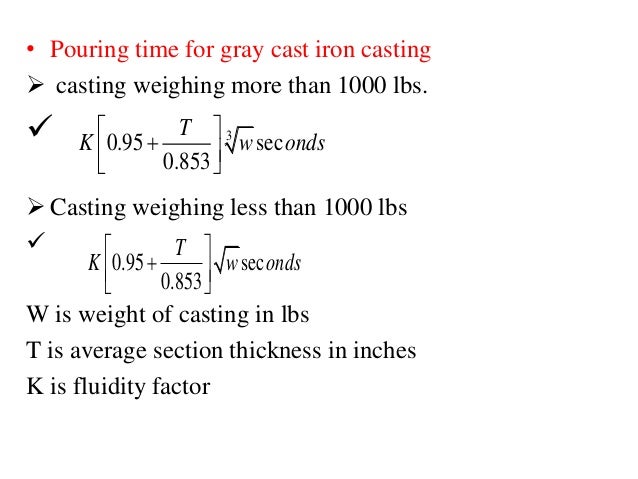

11 Heat transfer criteria M C. The design of gating system and riser is one of the major factor for improving the casting quality and yield. Weight of the riser 3 minimum x 20 kg 060 kg or 600 gr. Various types of gating systems are in practice depending upon size complexity weight and method of production of castings. Casting as a manufacturing process to make complex shapes of metal materials in mass production may experience many different defects such as porosity shrinkage blowhole and incomplete filling. Design of gating system will help to pour molten metal into mold cavity before solidification temperature of aluminium alloy. M F 1. CALCULATION OF FEEDER SIZE The feeder must satisfy both of the following two requirements. On having a closer look this is a partially pressurized system.

A turbulence metal flow tends to form dross in the mold. Only that portion of the riser which is higher than the highest point of the casting to which it is attached will compensate for liquid contraction in the casting. A gating system should fill the mold cavity completely before freezing. As geometry is complicated and component is bulky we have. Input initial mold height ht casting height mold thk1 inch min in our case ht h004 010040140 mtr t h_casttm. Total runner CSA B. Proper gating system will help to avoid turbulence flow of.

Post a Comment for "Gating System Design Calculation Pdf"